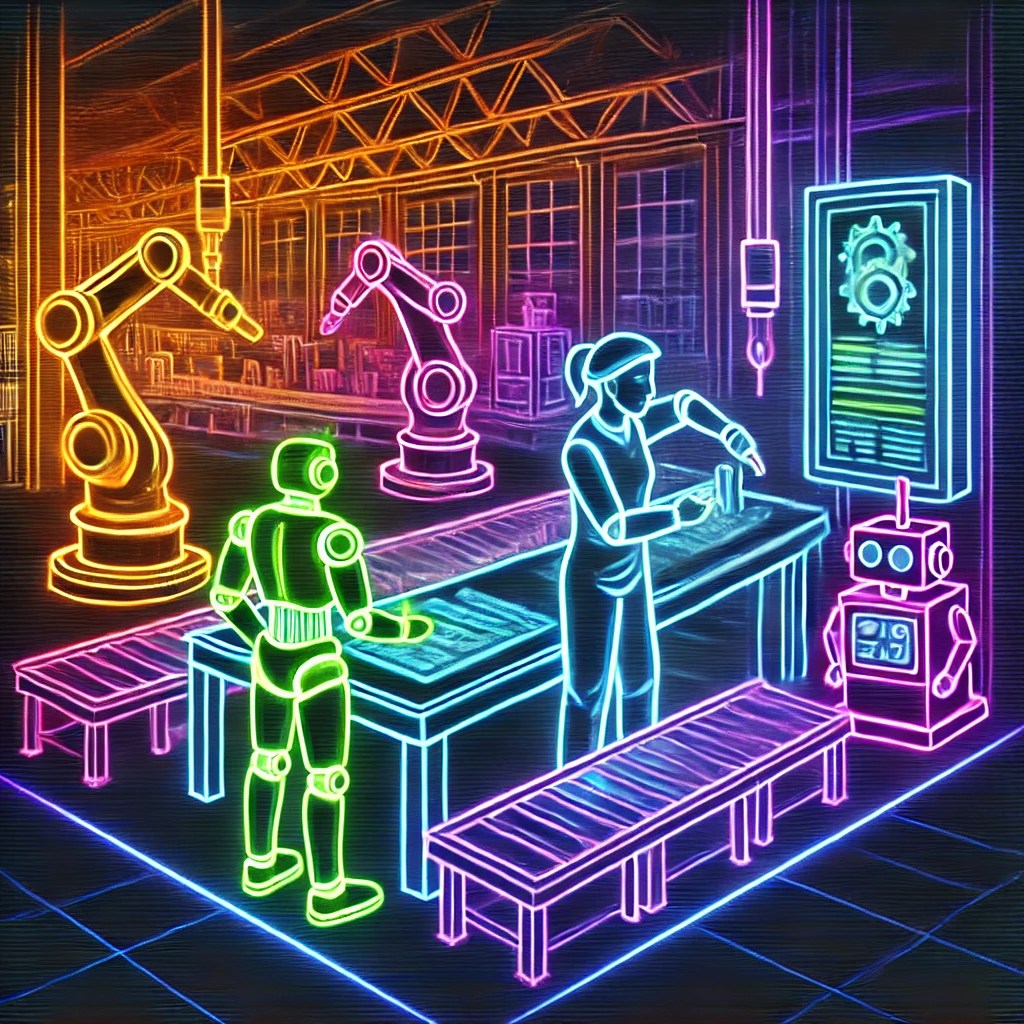

On a factory floor in Copenhagen, Lars, a seasoned craftsman, stands beside a sleek, silver robot. Together, they assemble custom-designed bicycles; Lars, with the precision honed by decades of experience, and the robot, mirroring his every move to tighten bolts perfectly. This seamless collaboration isn’t a scene from a sci-fi film but a snapshot of Industry 5.0, an era that brings humans back to the heart of manufacturing.

From Steam Engines to Smart Factories: A Historical Overview

To grasp Industry 5.0’s impact, we must revisit the milestones of past industrial revolutions:

- Industry 1.0 (Late 18th Century): The birth of mechanization, where steam engines powered factories, revolutionizing production.

- Industry 2.0 (Early 20th Century): The era of electricity and mass production, marked by Henry Ford’s assembly lines.

- Industry 3.0 (Late 20th Century): The rise of computers and automation, introducing programmable logic controllers and robotics.

- Industry 4.0 (Early 21st Century): The digital revolution, utilizing IoT, big data, and AI to create smart factories.

Each revolution enhanced efficiency but gradually distanced humans from the production process. Industry 4.0’s focus on automation sparked fears of machines replacing jobs. Enter Industry 5.0, a transformative approach where humans and machines collaborate seamlessly.

Key Principles of Industry 5.0

1. Human-Machine Synergy

At Industry 5.0’s core is the blend of human creativity and machine precision. Unlike Industry 4.0’s automated systems, this new era values human problem-solving, emotional intelligence, and adaptability.

“Machines excel at tasks they’re programmed for, but they can’t match a human’s ingenuity and empathy,” says Dr. Elena Martinez, an industrial engineering expert. “Industry 5.0 harnesses the strengths of both.”

2. Sustainability

Environmental stewardship is now imperative. Industry 5.0 emphasizes eco-friendly practices, aiming for zero waste and minimal carbon footprints. By optimizing resources and integrating renewable energy, companies can gain economic and environmental advantages.

3. Resilience

The COVID-19 pandemic exposed global supply chain vulnerabilities. Industry 5.0 aims to build robust systems that withstand disruptions, be they from pandemics, cyber threats, or climate change.

4. Personalization

Today’s consumers demand products tailored to their preferences. Industry 5.0 enables mass customization, delivering personalized products efficiently. This approach not only boosts customer satisfaction but also opens new market avenues.

Technologies Driving the Revolution

Collaborative Robots (Cobots)

Cobots are designed to work alongside humans safely. Unlike traditional robots confined by safety cages, cobots detect human presence with sensors, reducing accident risks.

For instance, Universal Robots’ cobots assist in packaging and assembly, taking on repetitive or ergonomically challenging tasks. This not only enhances productivity but also reduces workplace injuries.

Artificial Intelligence (AI)

AI analyzes vast data sets to optimize processes. In Industry 5.0, AI aids decision-making rather than replacing it. It predicts maintenance needs, optimizes supply chains, and even supports design processes.

Internet of Things (IoT)

IoT devices connect machinery, tools, and systems, enabling real-time communication and data sharing. This connectivity ensures seamless coordination throughout the production process.

Digital Twins

A digital twin is a virtual model of a physical system. Simulating processes in a digital environment allows companies to test changes, predict outcomes, and identify potential issues before they occur in the real world.

Siemens uses digital twins to optimize manufacturing, achieving a reported 40% increase in efficiency.

Industry 5.0 in Practice

Adidas’ Customized Footwear

Adidas’ Speedfactory showcases Industry 5.0 principles by combining human craftsmanship with automation to produce customized sneakers tailored to individual preferences. This approach has cut production times and enabled localized manufacturing.

Procter & Gamble’s Resilient Supply Chains

Procter & Gamble used AI and IoT to develop flexible manufacturing systems. During the pandemic, they quickly adapted to produce essential goods, highlighting Industry 5.0’s resilience aspect.

The Workforce at the Center

Advanced technologies raise concerns about job displacement. However, Industry 5.0 focuses on upskilling and reskilling workers for roles machines can’t fill alone.

A World Economic Forum report suggests that while automation might displace 85 million jobs by 2025, it could also create 97 million new roles, many requiring skills in AI management, robotics maintenance, and data analysis.

Educational Programs

Companies and governments are investing in training. For example, Toyota’s Technical Skills Academy educates employees in advanced manufacturing, ensuring their continued value in the evolving industry.

Challenges and Opportunities

Investment Challenges

Implementing Industry 5.0 technologies demands significant capital. Small and medium-sized enterprises might struggle with the initial costs. However, long-term gains in efficiency and productivity often justify the investment.

Ethical Issues

With AI and data collection central to Industry 5.0, ethical concerns around privacy and decision-making transparency arise. Establishing clear guidelines is essential to address these issues.

Innovation Opportunities

Industry 5.0 paves the way for new business models and products. Embracing personalization can help companies tap into niche markets. Moreover, sustainable practices appeal to environmentally conscious consumers and benefit the planet.

A Human-Centric Future

Industry 5.0 marks a shift from seeing technology as a human replacement to viewing it as a collaborator. It’s about enhancing human capabilities, not diminishing them.

“We’re entering an era where technology empowers people to achieve more,” says futurist Amy Webb. “The focus is on amplifying human intelligence and creativity.”

Conclusion

As we approach this new industrial era, Industry 5.0 promises to reshape manufacturing and the nature of work itself. By fostering collaboration between humans and machines, emphasizing sustainability, and enhancing resilience, we can build a future that benefits businesses, workers, and society as a whole.

The real question is: Are we ready to embrace this human-centric revolution?

Call to Action

Stay informed on Industry 5.0. Whether you’re a business leader, employee, or curious observer, understanding these changes is crucial. Think about how you can adapt and contribute to this evolving landscape. Share this article with your network and spark a conversation about the future we want to create together.

References:

- World Economic Forum. “The Future of Jobs Report 2020.”

- Siemens AG. “Digital Twin Technology in Manufacturing.”

- Universal Robots. “Collaborative Robots in the Workforce.”

About the Author

Francesco Casi is a technology enthusiast and writer passionate about how humanity and innovation intersect. With a background in engineering, Francesco explores how emerging technologies are shaping our world.